Virtual unrolling for analysing rolled objects

Research

Project

The virtual unrolling project is part of the research conducted at the 3D Imaging Centre at DTU, where surface detection is one of the focus areas. The project was part of the general development activities within the LINX project, in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques. Further information: DOI: 10.1109/ICPR.2018.8545715

Challenge

The output of an X-ray Computed Tomography (CT) experiment is a 3D dataset arranged in slices. However, these slices are not alligend with the shape a rolled object. To study the surface of a rolled object, e.g. to read a text in a scroll, we need to virutally unroll it. To solve this, the individual layers need to be distinguished such that the object can be unrolled virtually.

Results

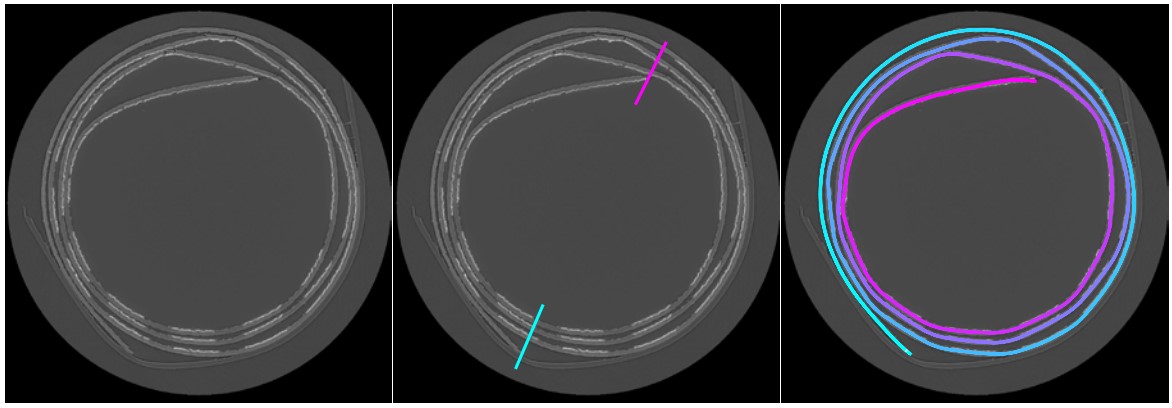

A piece of rolled microelectronics was scanned by X-ray micro CT using a ZEISS Xradia 410 Versa device. The individual layers have been found by a surface detection alogrithm using a semi-automatic approach. In this pilot study we manually indicated the start and end position of the rolled surface in a first step, as it is shown in the second figure from the top. Using the surface detection, both the polymer and metal layers were detected. This allowed us to visualize the unrolled printed piece also in its individual layers. While no crack in the conductive metal layer was observed, a crack was found in the polymer layer. This crack does not influence the functionality of this individual part, but this study shows that a similar process can be used to investigate rolled materials for cracks or other questions arising in quality control.

Perspectives

Virtual unrolling brings possibilities for e.g. studying the surface conditions of anodes and cathodes in rolled batteries, for identifying text in highly fragile scrolls or for other applications in cultural heritage and industrial inspection. Furthermore, it offers the option of rolling an object to fit better with the physical imaging restrictions, such that e.g. a better spatial resolution could be obtained.