Unravelling membranes' mysteries with X-ray

Improved Understanding of Membranes

Best known for its pumps, Grundfos also explores a number of other water technology solutions, including membranes. The company was in the process of evaluating a new type of membrane for waste water applications together with an international partner. In cooperation with the Imaging Industry Portal at DTU, Grundfos has been able to solve a small mystery regarding these membranes.

Chemical tests showed membranes from the two production sites to

be identical, but there was a systematic, significant difference in the

stability and long term performance which are key parameters for

membranes.

“We were puzzled to see that membranes produced at two different locations performed differently despite being manufactured from the same raw materials by principally the same method,”

Keen to use ESS and MAX-IV

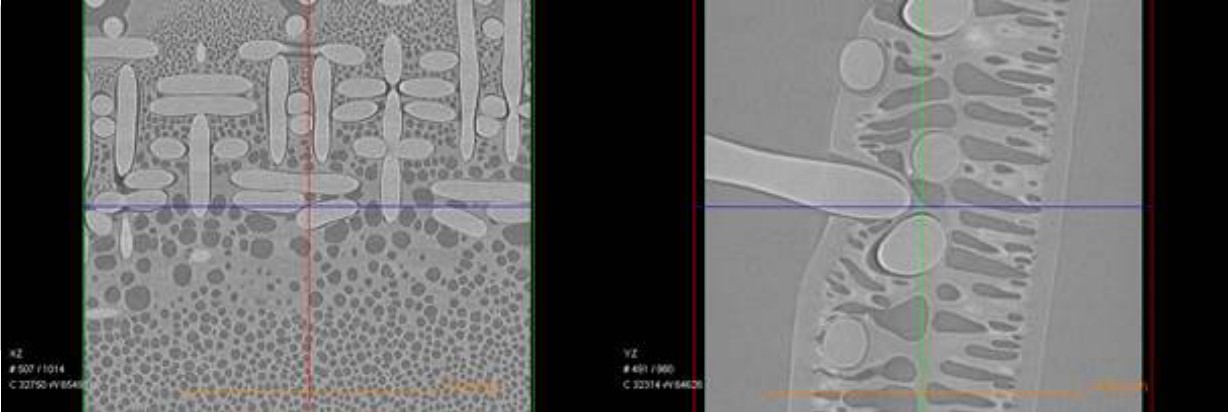

CT-scans (Computed Tomography) at DTU have revealed a difference in the distribution of tiny porosities inside the membrane polymer material. “The project was limited in scope, and has not explained what causes this difference, but it is an important step forward, that we can actually see a difference. This will help us in setting up a test regime. In other words we can vary production conditions and evaluate whether the change is positive,” Allan Hjarbæk Holm explains. “It is a general industry experience that you need to control manufacturing conditions extremely carefully when making polymer membranes, so in that respect we are not unique here. However, it is good news that we have a tool for improving things now.

CT-scans (Computed Tomography) at DTU have revealed a difference in the distribution of tiny porosities inside the membrane polymer material. “The project was limited in scope, and has not explained what causes this difference, but it is an important step forward, that we can actually see a difference. This will help us in setting up a test regime. In other words we can vary production conditions and evaluate whether the change is positive,” Allan Hjarbæk Holm explains. “It is a general industry experience that you need to control manufacturing conditions extremely carefully when making polymer membranes, so in that respect we are not unique here. However, it is good news that we have a tool for improving things now.

The project also served a larger purpose.

“We were keen to see how advanced materials science facilities

could be relevant - not least as new large-scale facilities are being

built in Lund, Sweden. The project shows that it will indeed be meaningful in our context,” says Allan Hjarbæk Holm.

More than just spectroscopy

An interesting feature of the ESS and MAX-IV facilities is that they will be able to cover a wide spectrum from traditional hard industry materials over softer materials like membrane polymers, and also biological samples. “It has not been tradition in waste water treatment to use advanced scientific equipment, but that could be about to change,” Allan Hjarbæk Holm notes.

More than just spectroscopy

An interesting feature of the ESS and MAX-IV facilities is that they will be able to cover a wide spectrum from traditional hard industry materials over softer materials like membrane polymers, and also biological samples. “It has not been tradition in waste water treatment to use advanced scientific equipment, but that could be about to change,” Allan Hjarbæk Holm notes.

Such future projects are likely to be performed in cooperation with

the Imaging Industry Portal at DTU, the Senior Development Engineer imagines:

“We have seen in the project on membranes that it is not just

about the spectroscopy itself. You need some follow-up loops in order to clarify things and obtain value from the experiments. The DTU

researchers have proved able to understand the issues we are facing

and deliver results in a useful format.”

Grundfos and DTU are currently discussing further joint projects in

imaging.

"We have seen in the project on membranes that it is not just about the spectroscopy itself. You need some follow-up loops in order to clarify things and obtain value from the experiments."