Investigating the quality of multimaterial interfaces

Challenge

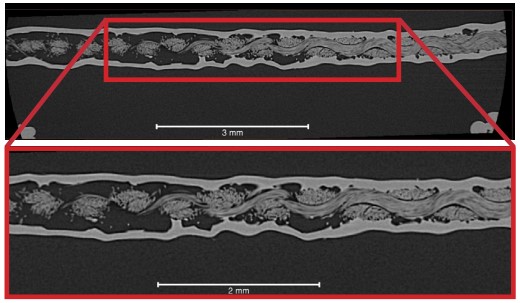

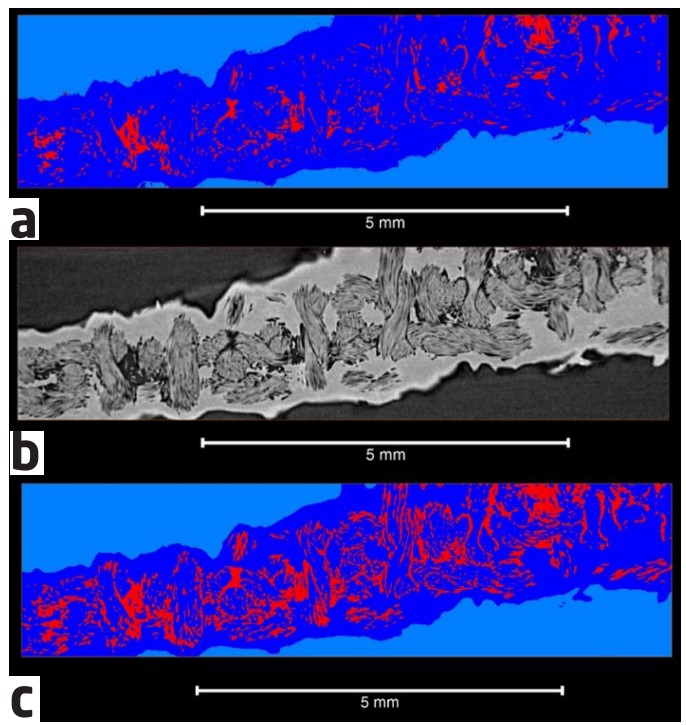

The parts of interest have a sandwich-like structure: at most positions, an outer layer of aluminium encapsules a polymer, which itself surrounds a woven textile. In this project, it is of interest to evaluate how deep the different polymers penetrate into the woven fibre structure and if there are differences between positions with and without aluminium encapsulation. However, it is a difficult task for image analysis to differentiate between the polymer and the fibres, especially when they are in close contact since there is hardly any contrast difference between them due to similar absorption properties. Therefore, we focus on an indirect measure by determining the amount of air which is present in this polymer-textile-zone. This task can be solved using image analysis by a so-called segmentation between air and material.

Collaboration

Through the collaboration between VELUX and the 3D Imaging Centre at DTU, sandwich-structures containing different polymers were characterised using X-ray micro Computed Tomography and subsequent image analysis. This collaboration was part of the LINX project, in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques.

Results

Air absorbs X-rays less than polymer or textile and therefore appears darker in the image. Two different methods for image segmentation were tested. The first was simple thresholding according to the grey scale intensity, i.e. by how dark or bright the material appears. The other method, which used a “top hat transformation” additionally focused on the extraction of small and dark areas. The second resulted in a better segmentation of the air since also the air between the individual fibres was taken into account. Applying both methods to samples with different polymers, the same trends were found. The air content was higher in the parts which are not encapsulated by the aluminium layer. Additionally, one polymer showed significantly more air than the others, which can be interpreted as a worse penetration of the polymer into the material. This is shown qualitatively in the images on the left. For reliable statistical conclusion, the above mentioned process would be applied on more samples