Analysis of roof windows

Challenge

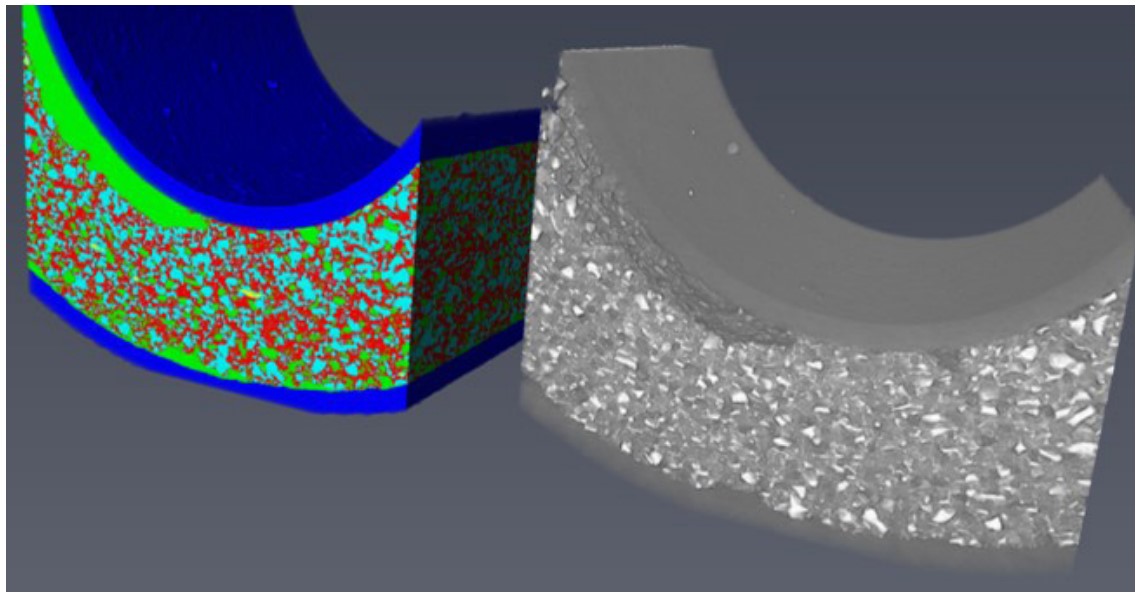

In this project, the company is interested in studying the structure of a corrugated sandwich of materials after processing, installation and different operational exposure conditions. Effects might be visible on various length scales and changes might occur on the outside, but also within the sample. Using X-ray Computed Tomography (CT), it is possible to penetrate the whole material and obtain a 3D image of the studied sample. First, overview measurements on the whole sample were performed. Then, higher resolution measurements were performed by zooming into selected areas. In this way changes at different length scales are covered best. The materials in the samples differ in both density and chemical composition, which results in a different degree of X-ray absorption. Therefore, the individual materials can be easily separated using a task known in image analysis as segmentation. Then, statistical analysis is used to determine the amount of one material relative to another one, e.g. to determine the content of air.

Collaboration

Through the collaboration between VELUX and the 3D Imaging Centre at DTU, the parts that had been exposed to different conditions were characterized using micro X-ray CT scans and subsequent image analysis. This collaboration was part of the LINX project in which researchers at leading Danish universities collaborate with scientists in industry to solve industry-relevant problems using advanced neutron and X-ray techniques.

Results

Using image segmentation, four materials with different absorption properties were be detected: a very strongly absorbing component of high (electron) density, which appears very bright, another strongly absorbing material, also bright, a less absorbing matrix in grey, and some internal air, present as dark voids. While the composition of the matrix and the stronger absorbing parts does not change significantly between the samples, significant differences could be seen in the amount of air present in the sample. However, this is likely related to the variability due to sample preparation. In addition to these findings, differences on the outside of the material were observed, such as a degradation of the surface.