Improving the image quality of high-speed data

Challenge

The 3D images obtained from the X-ray experiment at the synchrotron contained noise and artefacts, which made visualization challenging. To facilitate image analysis, we decided to repeat the reconstructions of the 3D images and perform a subsequent filtering to obtain a better quality of the 3D images.

Collaboration

Novo Nordisk got in contact with the 3D Imaging Centre at DTU through the LINX project, in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques. In this part of the project, the researchers at the 3D Imaging Centre at DTU made use of tools which were developed in the “P3- Predicting Petrophysical Parameters for evaluating oil reservoirs” project. The project was previously conducted at University of Copenhagen and Mærsk Oil & Gas and funded by the Innovation Fund Denmark as grant number 5184-00034B.

Results

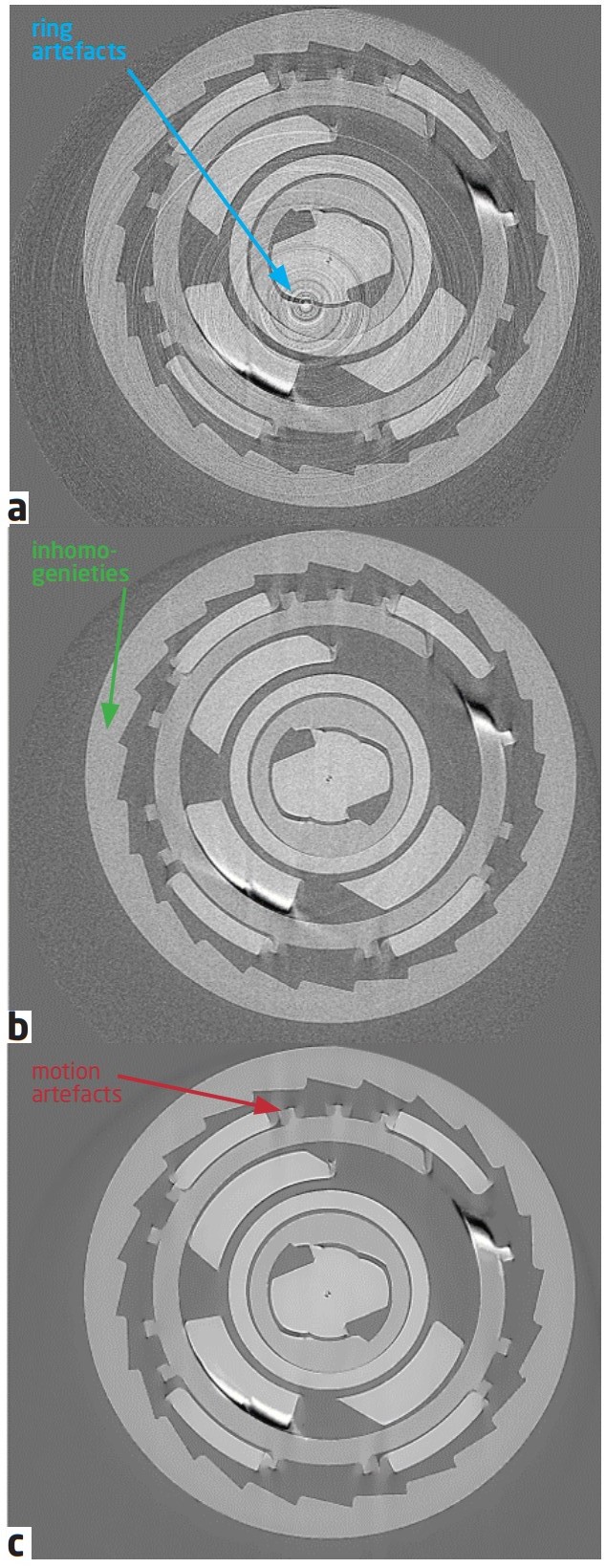

As the internal parts of the insulin pen move with a higher speed than the image acquisition took place, artefacts due to movement were expected and cannot be corrected for. These motion artefacts can e.g. be seen by smirred edges as indicated on the bottom figure on the left. Besides these motion artefacts, the immediately at the synchrotron reconstructed images also contained a huge amount of noise appearing in the form of so-called “ring artefacts”, which are visible as a number of rings around a center, as indicated in the top part of the figure on the left. When re-reconstructing and correcting for these artefacts, an image without those ring artefacts is obtained, as it can be seen in the middle image on the left. After correction for these artefacts, the image was filtered such that inhomogenieties in grey values were reduced and the edges of the individual parts became more obvious, as it can be seen in the bottom image. The different corrections made a more precise identification of the individual components possible. The 3D images with improved image quality were then used as input for further analysis and visualization steps in this project.