Folding of packaging materials

Challenge

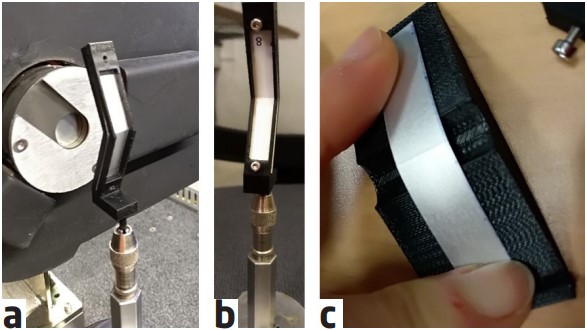

In order to study how the different layers of the packaging material react when they are folded at different angles, a set of holders and support tools were developed. The holders allow the same position of the material to be studied using X-ray micro computed tomography when folding at 0° , 45°, 90° and 180°. To prevent the material from overbending, and to allow for geometrical flexibility during folding, support tools were fabricated for 45° and 90° folding angles, as shown on the pictures on the left.

Collaboration

Through the collaboration between Tetra Pak and the 3D Imaging Center at DTU, the material was characterized using micro X-ray computed tomography scans and in-house developed analysis tools. This collaboration was part of the LINX project, in which researchers at leading Danish universities collaborate with scientists in industry to solve industry-relevant problems using advanced neutron and X-ray techniques.

Results

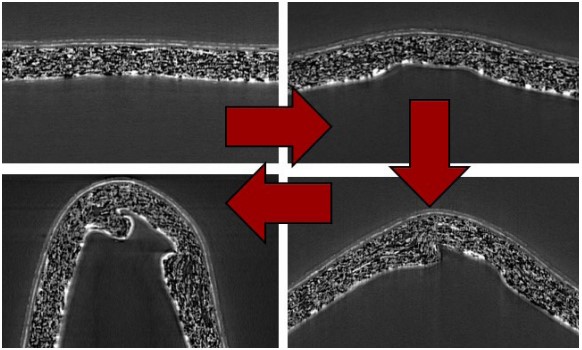

During production of packaging material, crease lines are made on the paper board before lamination of additional layers. These crease lines facilitate folding the material into a packages. The different crease lines are mainly oriented along or across the production direction. In this project, the same material was studied while looking at two differently oriented crease lines. Furthermore, two different folding directions were studied: folding the inside of the packaging material inwards, or folding the outside of the packaging material outwards. In total, this enabled us to study four different folding series with four folding angles for each series. To process and visualise the acquired data, a stitching method, allowing for sideways stitching and aligning the samples, was developed. By that, the individually acquired, but overlapping, tomograms with a pixel size of 4.2 µm could be merged.

Perspectives

The purpose of this project is to obtain geometric input for modelling and simulation processes. Therefore, the acquired data is going to be used for further analysis to deduce information on how the layered material behaves when being folded at different angles.