Study of voids in roof window components

Challenge

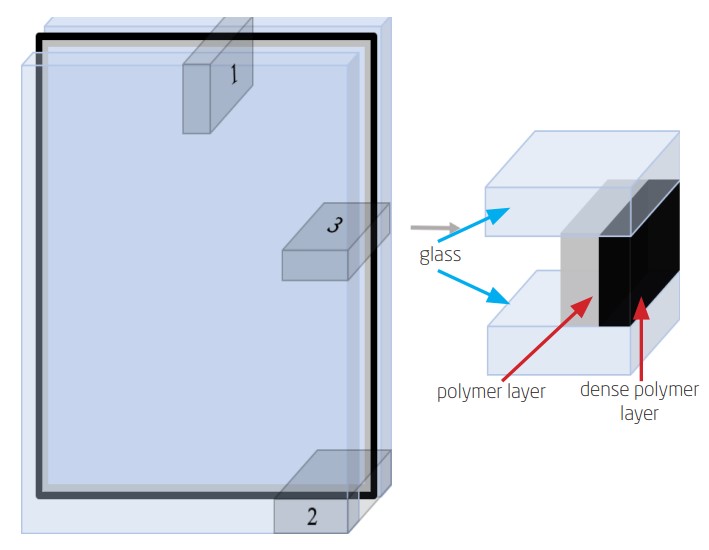

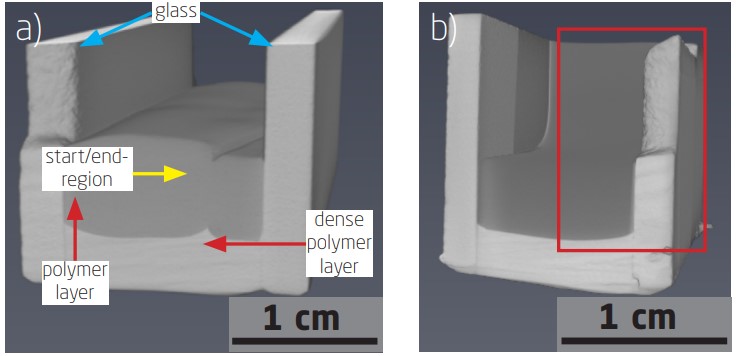

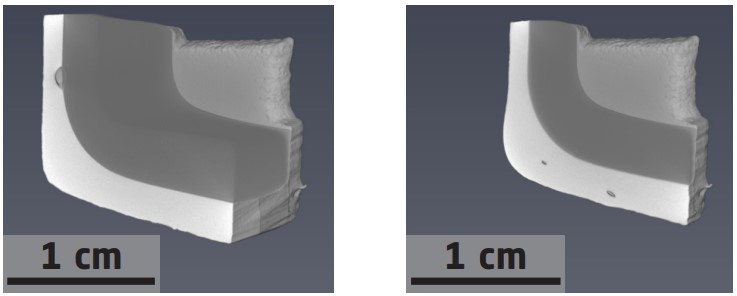

As thermoplastic spacers play a significant role in insulation and sealing of a window unit, the occurrence of crevices or connected voids within the spacer materials allows ingress of moisture which can be followed by a reduction of the insulation of the window. When cutting the material to look for crevices, there is a risk in causing them by the sample preparation process. X-ray CT however offers to analyse the occurrence and composition of voids and crevices in a volume nondestructively. Here, three different areas of a window were studied in order to examine the material at different places. While sample 1 was taken at the position where the insertion process of the polymers into the window frame was started/ended, sample 2 was chosen to be at a corner of the window and sample 3 at a side of the window.

Collaboration

Through the collaboration between VELUX and the 3D Imaging Centre at DTU, the thermoplastic spacers were analyzed using micro X-ray computed tomography scans and image analysis. The collaboration was part of the LINX project in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques.

Results

The three samples were analysed at different spatial resolutions to look for bigger and smaller voids using a ZEISS Xradia Versa 410 CT scanner. The physical extent of the samples set a practical limit for the highest spatial resolution to be obtained. This means that smaller voids might exist, but could only be studied with further sample preparation. While no voids were visible in sample 3, one could visualise the start/end region of the polymer insertion process and one void in sample 1. However, this void was small and not connected to the surface. Sample 2 revealed a few voids within the dense polymer and inbetween the polymer layers. Nevertheless also at this corner position, no connection between the voids and the surface of the window unit could be seen, meaning that the voids are at a very low risk of serving as an entrance route for water from the surroundings. This study therefore shows, that X-ray CT is a suitable tool for quality assurance of window components on a micrometer level.