Artificial intelligence used in characterisation of porosity

Challenge

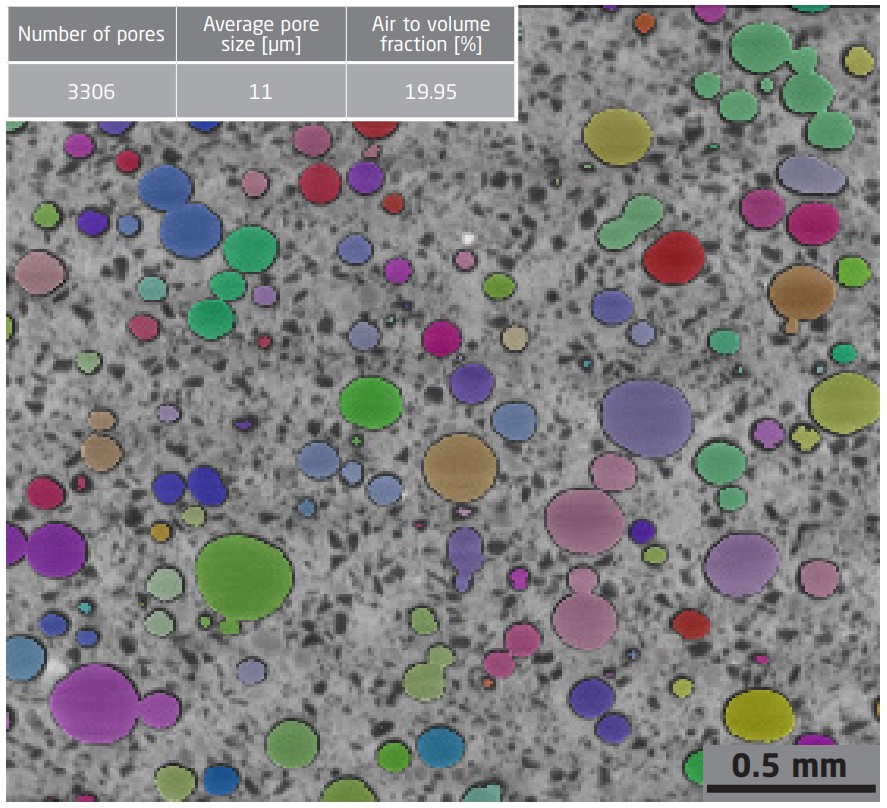

The polymer samples under study are composed of two types of polymer and air. Even though the three components can be easily distinguished in the images by the human eye, a simple automatic image analysis method that relies on the image intensities would not be able to differentiate between the lower density polymer and the air pores of similar image intensity. Therefore, to study just the air we had to use a machine learning method based on neural networks.

Collaboration

Through the collaboration between VELUX and the 3D Imaging Centre at DTU, a range of samples was imaged in house with X-ray CT and analysed subsequently at the Imaging Center. This collaboration was part of the LINX project in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques.

Results

To help VELUX with the characterisation of their samples, we built an analysis pipeline to determine the size and location of pores using artificial intelligence. We employed a well-known deep neural network architecture (called the U-net) for the task of differentiating between air and polymers. The U-net was trained to learn the appearance of the pores in the samples, using a subset of 2D images where we marked the pixels corresponding to air manually. The neural network was then used to find all the air pixels in each 3D volume. Afterwards, an air pore, defined as a region of connected air pixels, was characterised through its position and size. From these measures, we produced pore size distributions for each sample and computed the percentage of air within each sample.

Perspectives

In the future, this method could also be used locally, that means on sub-regions of the whole sample, to study the distribution of air pores and thereby reveal spatial variations in air content. In fact, the method could work for other materials than polymer and air as well, as long as the X-ray signal differs