Investigation of gypsum after high temperature exposure

Challenge

The porosity of materials is commonly determined by bulk analysis methods, e.g. by looking at how much of a specific gas or mercury is needed to fill the pore space of the studied material. In contrast, X-ray Computed Tomography (CT) offers a non-destructive imaging method which results in a 3D representation of the studied sample. Therefore, it allows to both visualise the material and study the pores and their connectivity, but at limited resolution.

Collaboration

Through the collaboration between DBI and the 3D Imaging Centre at DTU, the gypsum pieces were characterised using in-house X-ray CT. This collaboration was part of the LINX project, in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques. Besides performing projects for the members of the LINX association, the LINX project also supports outreach projects for companies which are not members of the LINX association. In this way, companies can test how they can profit from X-ray- and neutron-based techniques.

Results

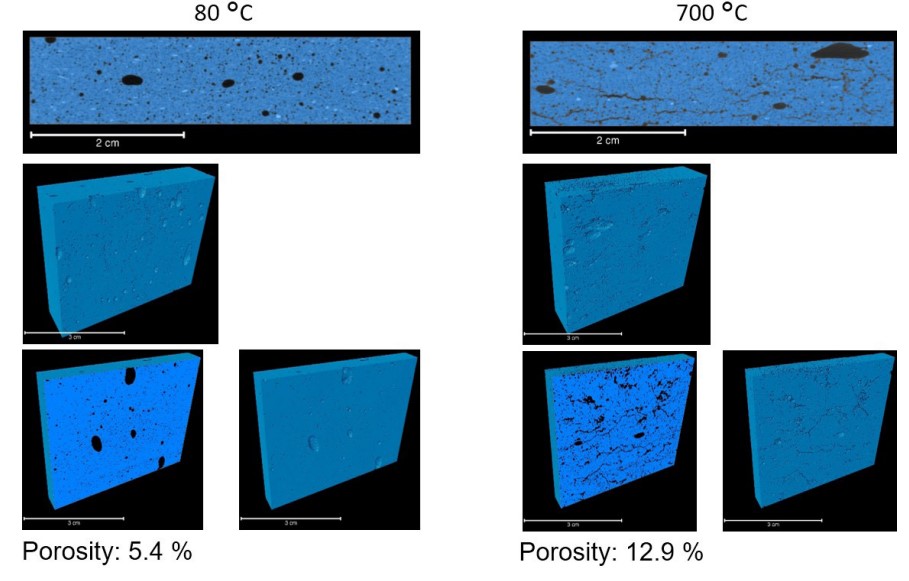

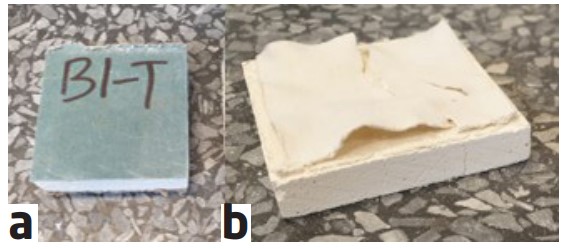

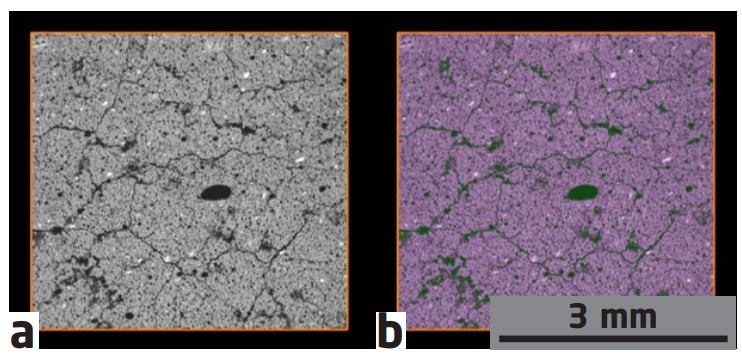

A series of five gypsum samples exposed to temperatures ranging from 80 °C to 700 °C was studied using X-ray CT. Then, image analysis was used to differentiate between the air, in dark, and the gypsum, in bright. By that, the porosity (fraction of air in respect to the total volume) could be determined. With increasing temperature, an increase in porosity could be seen. In addition, the visual inspection of the scan revealed cracks in samples treated above 300 °C.

Perspectives

Here, only the porosity was used as an input to the simulation, but the approach also allows incorporating the actual geometry of air within the sample, which could lead to more accurate simulations.