Complex fibre analysis using X-ray imaging

Challenge

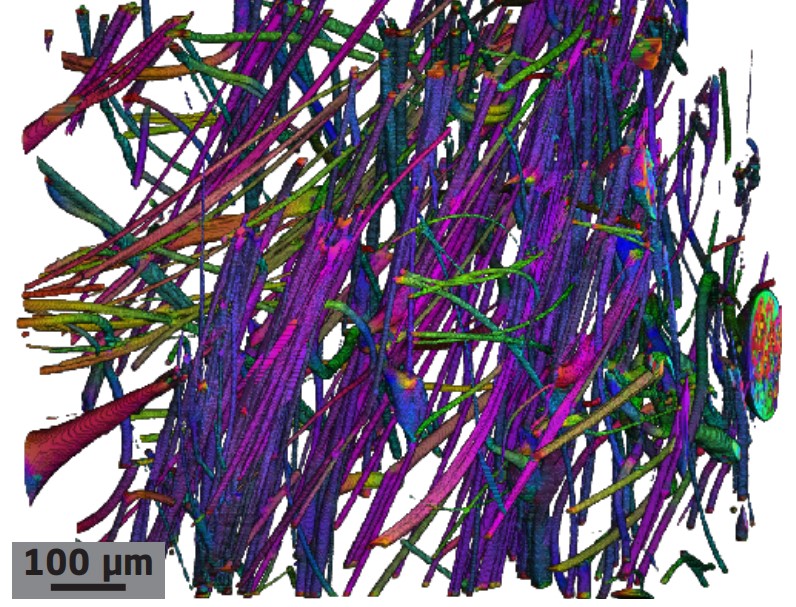

Mineral wool consists of fibers arranged in a complex network. The fibers can vary in diameter, length, orientation and curvature. All these parameters influence the final material properties, hence characterizing them helps to understand and thereby tune the material properties.

Collaboration

Through the collaboration between ROCKWOOL and the 3D Imaging Centre at DTU, the material was characterized using micro X-ray computed tomography scans and an analysis toolbox was developed in-house. This collaboration was part of the LINX project in which researchers at leading Danish universities collaborate with scientists in industry to solve industry relevant problems using advanced neutron and X-ray techniques.

Results

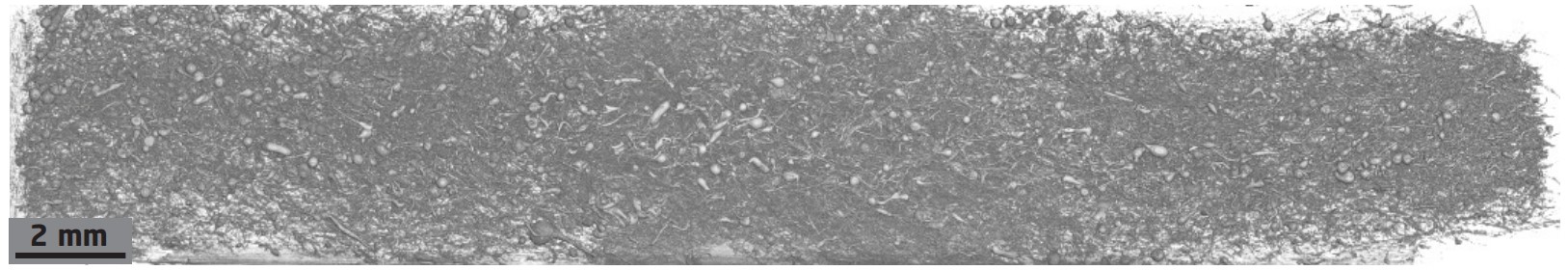

By performing several high resolution scans along the assumed dominating fibre direction, a large field of view was analyzed without compromising visibility of individual fibers. The developed analysis is based on the estimation of local orientations which are used to track and characterize individual fibers. It involves handling large amounts of data, detailed visualizations of the inner structure of mineral wool, and an analysis of material parameters such as orientation and diameters.

Perspectives

By this characterization of the fibers, ROCKWOOL could gain valuable input for simulations. Having this analysis toolbox enables similar analyses of future products.