VISUAL INSPECTION OF INTERNAL STRUCTURES

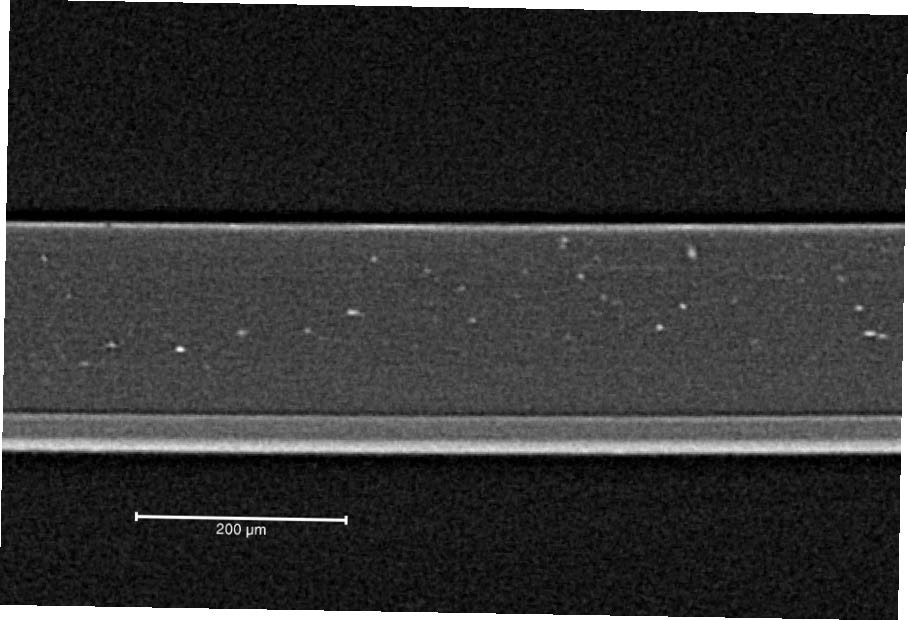

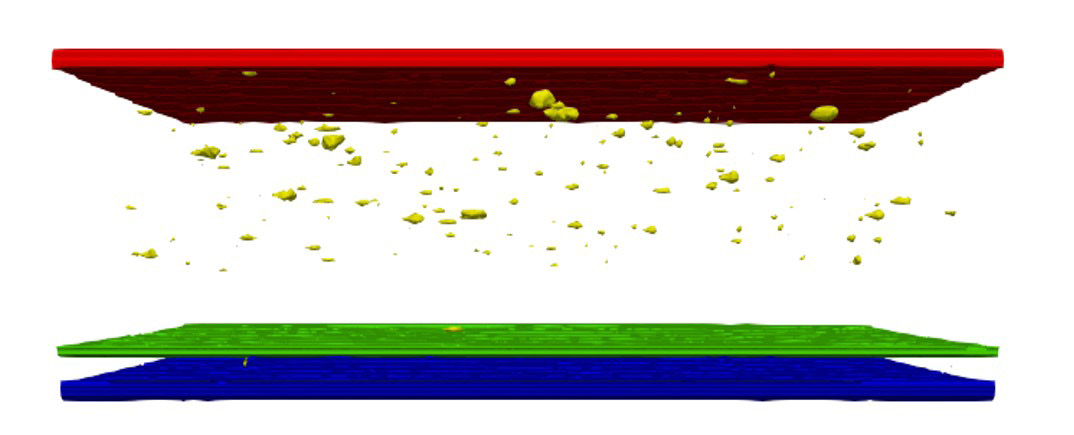

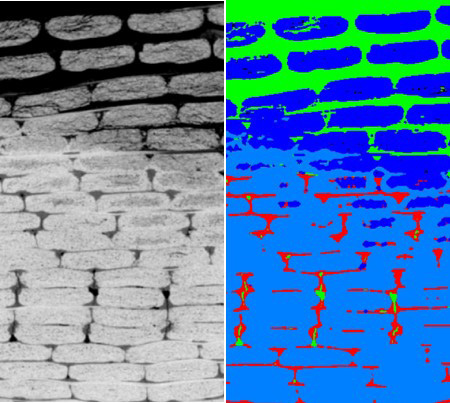

“A picture is worth a thousand words” is a saying that reflects a lot of our daily business, as we create three-dimensional images by X-ray CT. Often, our customers need to non-destructively look into their sample to see defects, to find out if cables are broken, to visualise cracks, to check if components are placed at the right position or to make a quality control and detect different layers. We provide non-destructive imaging of the studied sample and create a 3D dataset which can be studied by the customers dependent on their needs.

Movie showing a battery with the individual parts being shown in different colours.

We offer to provide:

- A full 3D visualisation of the sample

- A selection of images

- Movies

- A report including selected images of the sample

We previously looked at paper-based packaging materials, hearing aids, wind turbine blades, window components, material interfaces, coating layers or metal powders.